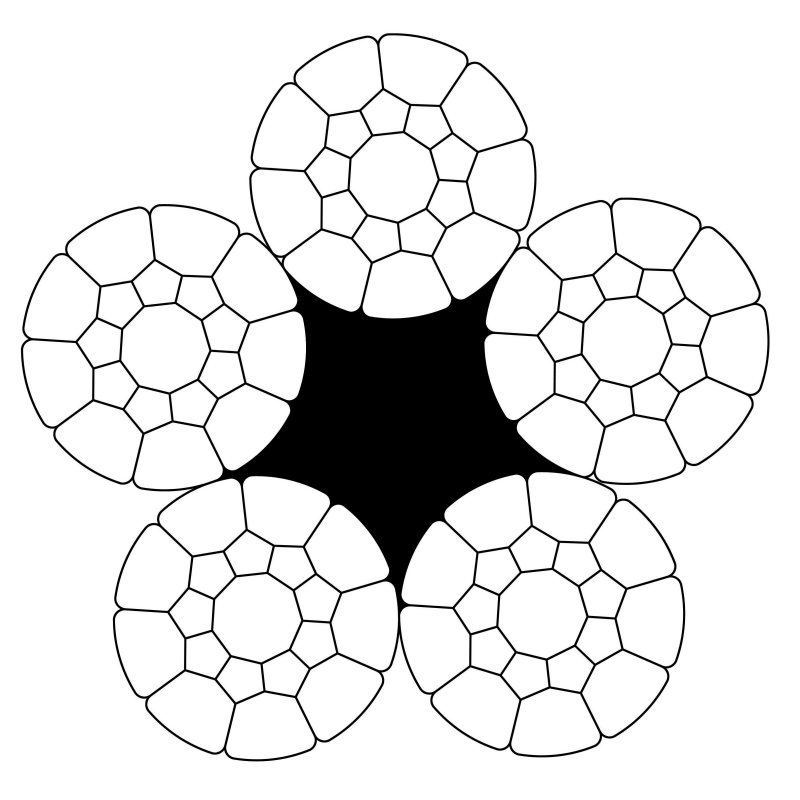

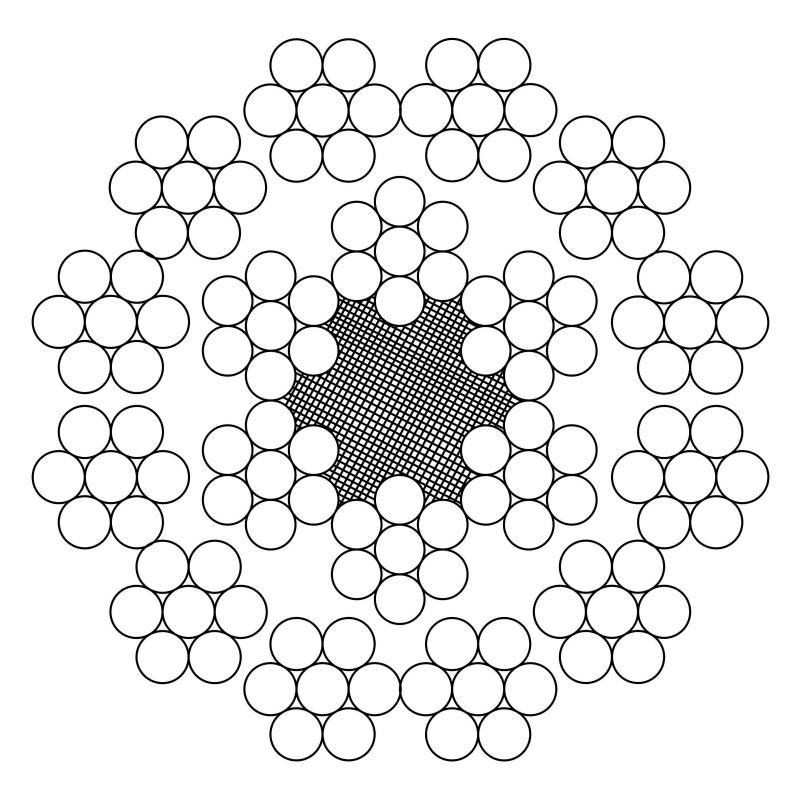

Product

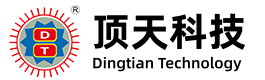

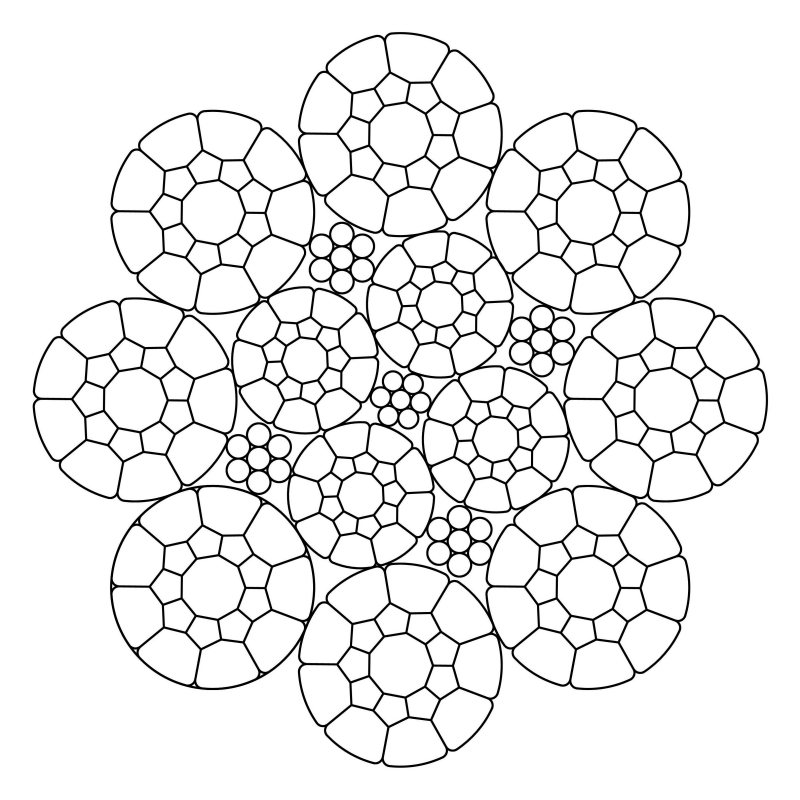

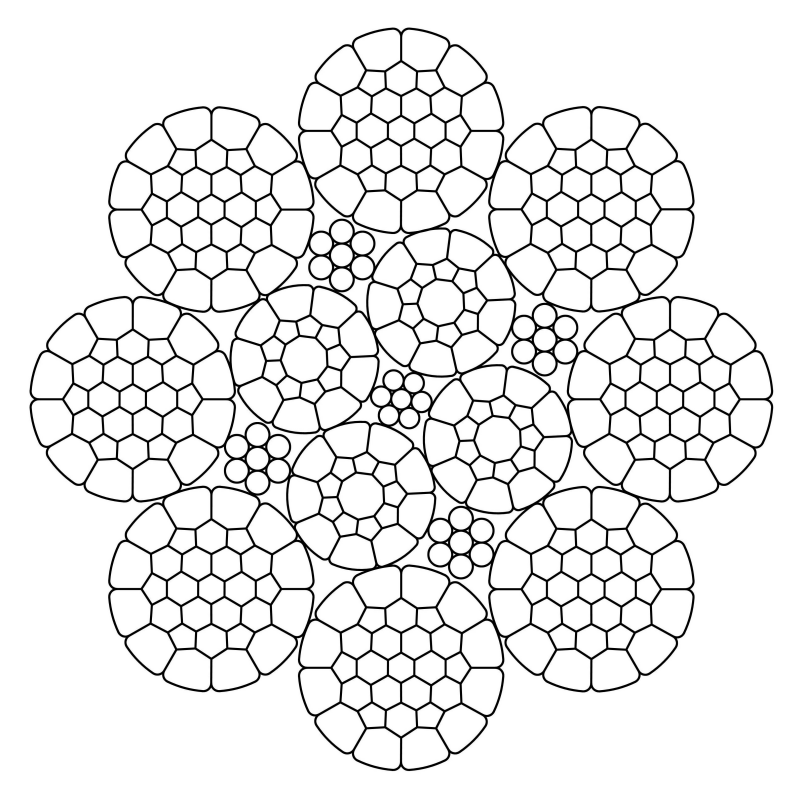

18×7-FC

一家专业从事钢丝绳的生产、研发、销售的公司,开发并生产为电梯绳生产企业做配套服务,重点为 6*19 的钢丝绳,同时兼做部分出口业务,以热镀锌钢丝绳为主

- Product details

-

187-FC wire rope parameter table

Nominal diameter of wire rope (mm) Reference weight (kg/100m) Wire rope minimum breaking tension (kN) FC WC 1570MPa 1770MPa 1960MPa 2160MPa FC WC FC WC FC WC FC WC 6 14.0 15.5 17.5 18.5 19.8 20.9 21.9 23.1 24.1 25.5 7 19.1 21.1 23.8 25.2 26.9 28.4 29.8 31.5 32.8 34.7 8 25.0 27.5 31.1 33.0 35.1 37.2 38.9 41.1 42.9 45.3 9 31.6 34.8 39.4 41.7 44.4 47.0 49.2 52.1 54.2 57.4 10 39.0 43.0 48.7 51.5 54.9 58.1 60.8 64.3 67.0 70.8 11 47.2 52.0 58.9 62.3 66.4 70.2 73.5 77.8 81.0 85.7 12 56.2 61.9 70.1 74.2 79.0 83.6 87.5 92.6 96.4 102 13 65.9 72.7 82.3 87.0 92.7 98.1 103 109 113 120 14 76.4 84.3 95.4 101 108 114 119 126 131 139 16 100 110 125 132 140 149 156 165 171 181 18 126 139 158 167 178 188 197 208 217 230 20 156 172 195 206 219 232 243 257 268 283 22 189 208 236 249 266 281 294 311 324 343 24 225 248 280 297 316 334 350 370 386 408 26 264 291 329 348 371 392 411 435 453 479 28 306 337 382 404 430 455 476 504 525 555 30 351 387 438 463 494 523 547 579 603 638 32 399 440 498 527 562 594 622 658 686 725 36 505 557 631 667 711 752 787 833 868 918 40 624 688 779 824 878 929 972 1030 1070 1130 44 755 832 942 997 1060 1120 1180 1240 1300 1370 48 899 991 1120 1190 1260 1340 1400 1480 1540 1630 52 1050 1160 1320 1390 1480 1570 1640 1740 1810 1920 56 1220 1350 1530 1610 1720 1820 1910 2020 2100 2220 60 1400 1550 1750 1850 1980 2090 2190 2310 2

related products

Product Inquiry

Please leave your message, we will contact you quickly after receiving it, thank you for your support!

common problem

Q

What kind of lubricant can prevent wire rope damage?

A

First, the smooth oil has good fluidity and soaking ability, allowing it to quickly enter the inside of the rope and the rope core when the wire rope is smooth pretreated, and can play a role in preventing bacteria from multiplying inside the rope core fibers.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Q

What are the classifications of wire ropes?

A

1, electric hoist wire rope: 6 * 37 + FC- 11/13/15/17.5

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

Copyright © 2012-202X Jiangsu Dingtian Technology New Materials Co., Ltd. All rights reserved

简体中文

简体中文 English

English