Product

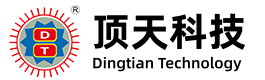

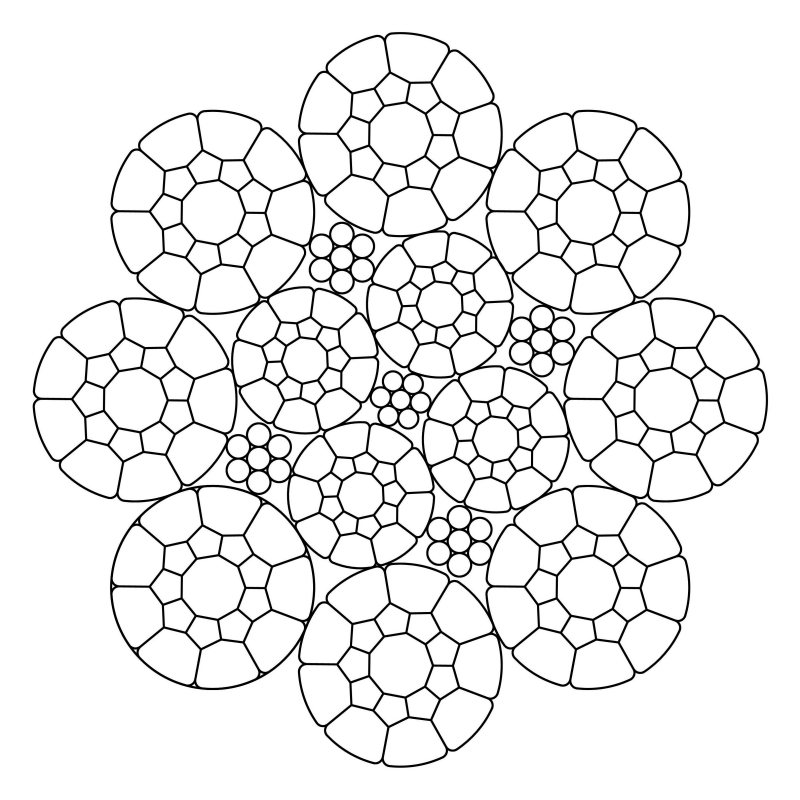

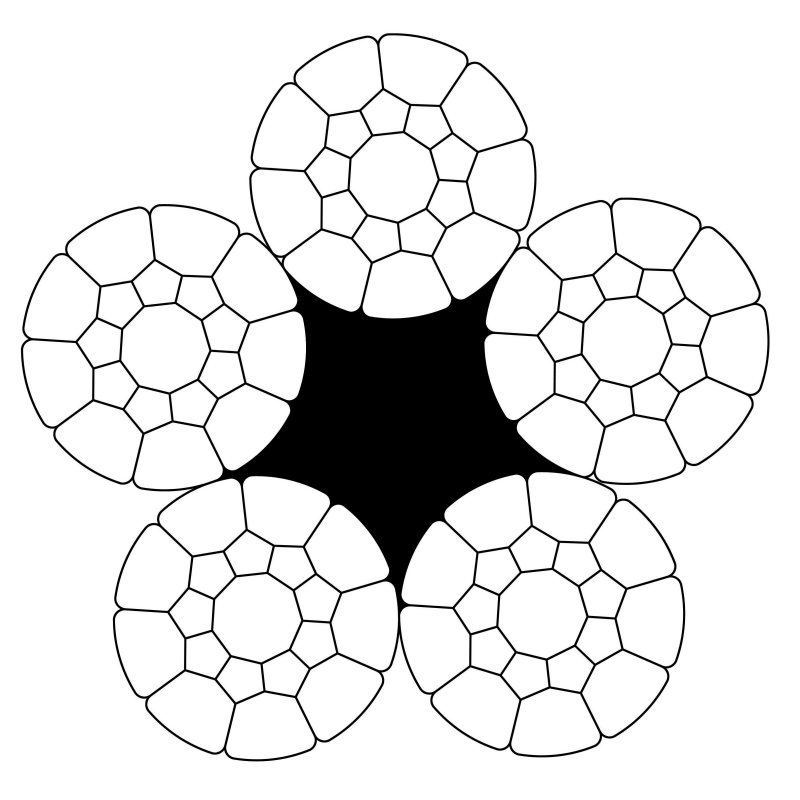

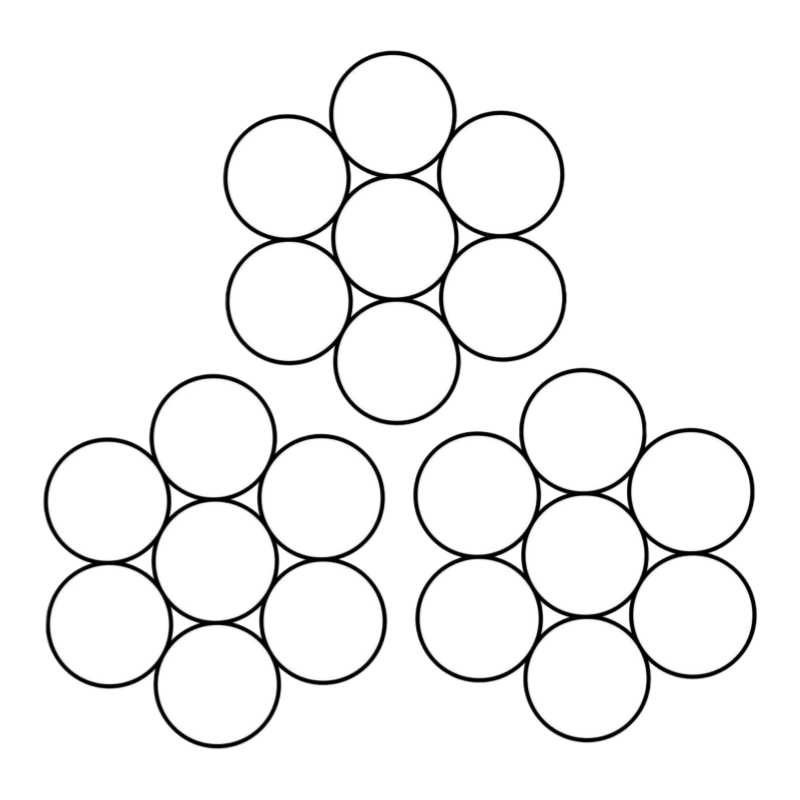

3×7

A company specializing in the production, research and development, and sales of steel wire ropes. It develops and produces supporting services for elevator rope manufacturers, focusing on 6 * 19 steel wire ropes. At the

- Product details

-

公称直径(d)

钢丝直径(d₁) 绳股直径(≈d/√3) 近似重量(kg/100m) 最小破断拉力(kN) 最小破断拉力(kgf) 适用场景 Nominal Diameter (d) Wire Diameter (d₁) Strand Diameter (≈d/√3) Approximate Weight (kg/100m) Minimum Breaking Load (kN) Minimum Breaking Load (kgf) Application Scenario 3mm 0.45mm ≈1.73mm 0.32 1.8 183 Small rigging, toy machinery 4mm 0.60mm ≈2.31mm 0.57 3.2 326 Light guy wire, curtain traction 5mm 0.75mm ≈2.89mm 0.89 5 510 Small hoist, fitness equipment 6mm 0.90mm ≈3.46mm 1.28 7.2 734 Agricultural machinery cable, small hanging basket 8mm 1.20mm ≈4.62mm 2.27 12.8 1306 Construction guy wire, marine auxiliary rigging 10mm 1.50mm ≈5.77mm 3.55 20 2039 Medium lifting equipment, mine support

related products

Product Inquiry

Please leave your message, we will contact you quickly after receiving it, thank you for your support!

common problem

Q

What kind of lubricant can prevent wire rope damage?

A

First, the smooth oil has good fluidity and soaking ability, allowing it to quickly enter the inside of the rope and the rope core when the wire rope is smooth pretreated, and can play a role in preventing bacteria from multiplying inside the rope core fibers.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Q

What are the classifications of wire ropes?

A

1, electric hoist wire rope: 6 * 37 + FC- 11/13/15/17.5

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

Copyright © 2012-202X Jiangsu Dingtian Technology New Materials Co., Ltd. All rights reserved

简体中文

简体中文 English

English