Product

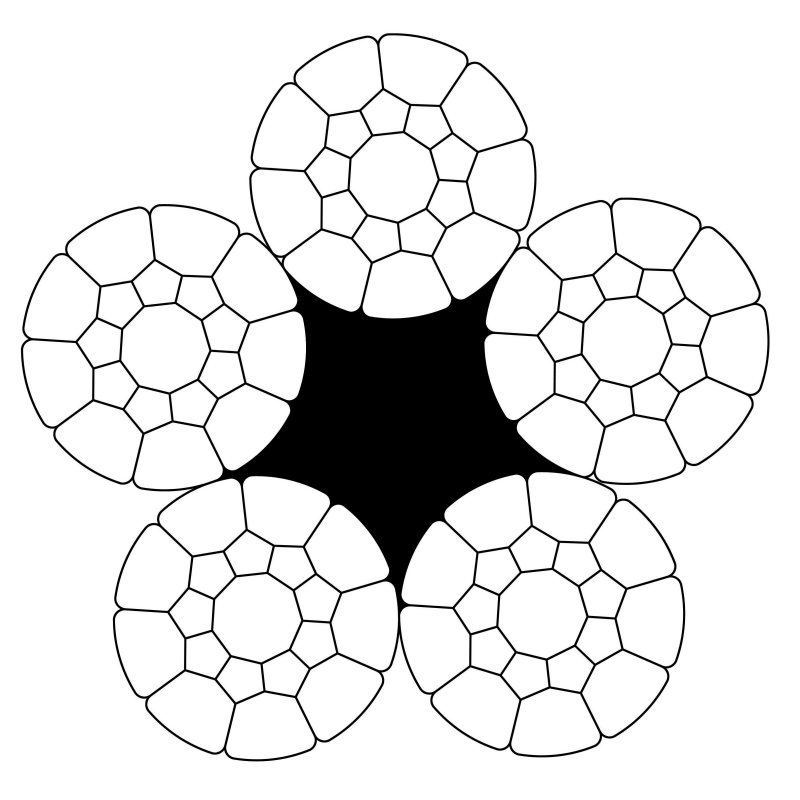

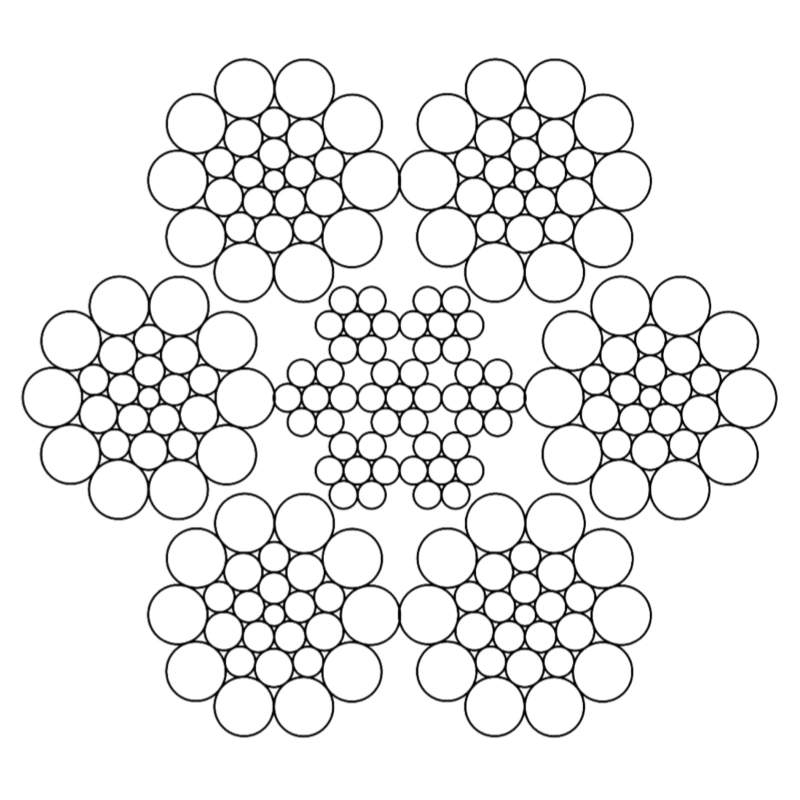

8×26WS+IWRC

A company specializing in the production, research and development, and sales of steel wire ropes. It develops and produces supporting services for elevator rope manufacturers, focusing on 6 * 19 steel wire ropes. At the

- Product details

-

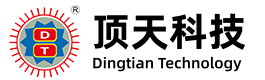

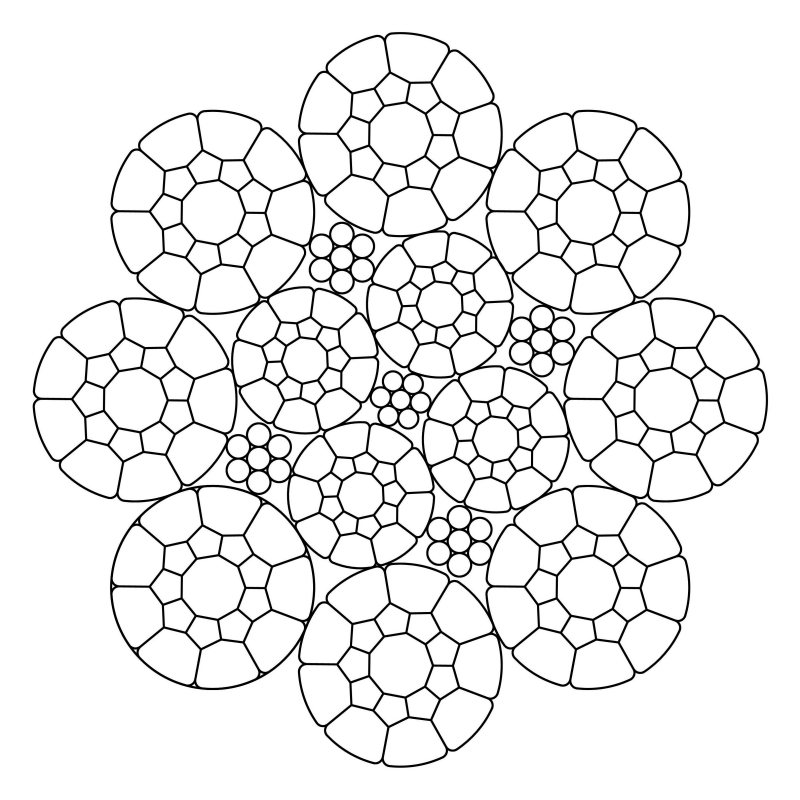

8×26WS+IWRC 是 8 股 ×26 丝(瓦林吞 - 西鲁复合结构)+ 独立钢绳芯 的线接触钢丝绳,结构紧凑、韧性均衡,兼具抗磨损、耐疲劳、中等承载能力的特点,符合 GB/T 20118-2017《钢丝绳通用技术条件》、EN 12385-4 标准,适用于中型起重机、建筑塔吊、港口辅助装卸、矿山斜井运输等中重载且需频繁弯曲的工况。

一、基础结构参数

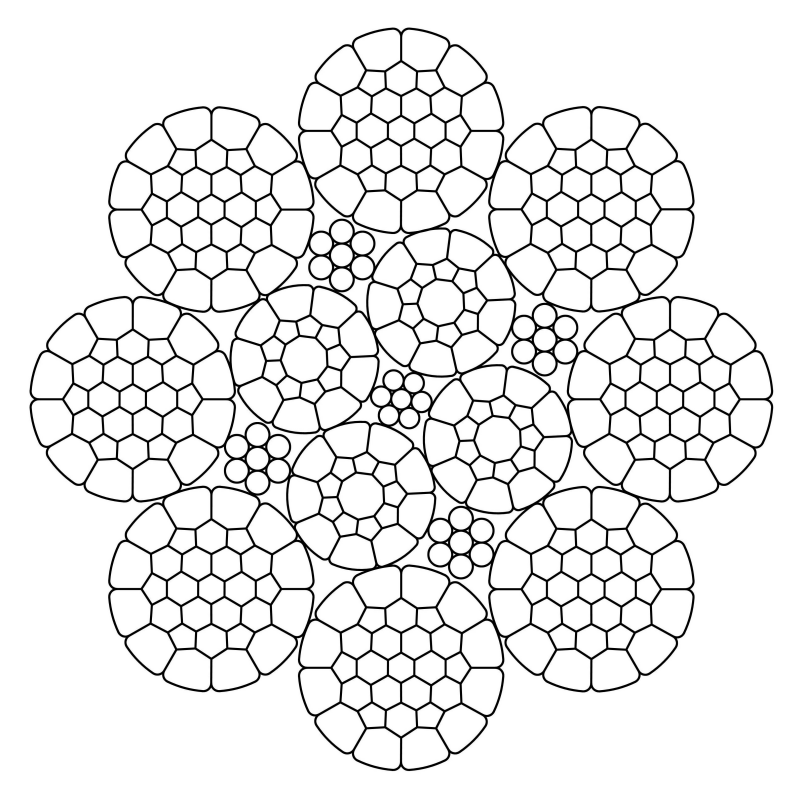

参数项 详细说明 结构组成 8 个外层股 + 独立钢绳芯(IWRC,常规为 7×7 结构);每股 26 丝,采用瓦林吞 - 西鲁(WS)复合排列(1-5-10-10 分层,粗细钢丝交替分布),线接触设计让股内钢丝受力均匀 钢丝材质 优质碳素结构钢(#60、#70、#72A),冷拔强化处理;高端型号可选热镀锌钢丝或合金钢丝,提升耐腐蚀性与抗磨损性能 表面处理 1. 光面:无镀层,适用于干燥无尘的室内工况2. 电镀锌:薄镀层(8~15μm),装饰性防锈,适用于轻度潮湿环境3. 热镀锌:厚镀层(30~60μm),强耐腐蚀,适用于户外 / 沿海 / 矿山腐蚀环境 直径范围 常见 14~48mm,主流应用 20~40mm 中重载提升场景 公称抗拉强度 碳钢型:1570MPa、1770MPa、1960MPa(工业常用 1770MPa 等级) 捻向 右同向捻(RHRL)、左同向捻(LHLL)、右交互捻(RHRH);8 股对称结构抗旋转性优于 6 股绳 重量系数 0.400~0.415(IWRC 芯参考值;热镀锌后重量增加 3%~5%) 最小破断拉力系数 0.355~0.365(结构密实度优于 8×19S 钢丝绳,金属截面积利用率更高) 二、详细力学性能表

1. 碳钢型(1960MPa,光面)

公称直径(mm) 参考重量(kg/100m) 最小破断拉力(kN) 适用场景 16 81.9 122 小型卷扬机、轻型起重机副钩 20 160 240 中型起重机副钩、建筑卷扬机 24 230 346 塔吊副钩、矿山斜井辅助运输 28 308 475 港口龙门吊副钩、建材吊装 32 402 618 大型履带吊副钩、风电塔筒辅助吊装 36 512 780 港口卸船机提升、盾构机配套牵引 40 640 960 重型塔吊主钩、预制构件吊装 48 900 1350 大型起重机主钩、重型设备搬运 2. 碳钢型(1770MPa,热镀锌)

公称直径(mm) 参考重量(kg/100m) 最小破断拉力(kN) 适用场景 20 166 214 户外建筑卷扬机、潮湿环境吊装 28 323 423 沿海港口辅助装卸、矿山斜井运输 36 538 697 海上平台辅助牵引、腐蚀环境起重 注:热镀锌处理后破断拉力比光面低 1%~2%;抗拉强度每降低一个等级,破断拉力约减少 11%~13%。三、核心特性

- 柔韧性与抗挤压均衡WS 复合股结构降低了股内钢丝的接触应力,搭配 IWRC 钢绳芯,既能适配中等直径卷筒(弯曲半径小),又具备良好的径向抗挤压能力,多层缠绕时绳体不易变形。

- 耐疲劳性优异线接触设计让钢丝受力均匀,反复起升、下放过程中,钢丝间摩擦损耗小,不易出现断丝、股松散问题,使用寿命比普通点接触钢丝绳长 25%~35%。

- 抗旋转性较好8 股对称分布的结构可抵消部分旋转力矩,作业时吊物扭转幅度小,避免因旋转导致的载荷偏移,适配长距离提升或下放工况。

- 性价比突出相比大丝数的 8×31WS、8×36WS 钢丝绳,该型号生产工艺更简洁,成本更低,同时能满足多数中重载设备的使用需求。

四、选型与使用要点

- 安全系数选择

- 中型起重 / 建筑吊装:5~6 倍

- 矿山运输 / 港口装卸:6~7 倍

- 严禁用于载人设备及高危重载工况

- 环境适配原则

- 干燥室内 → 光面碳钢绳

- 普通户外 → 热镀锌碳钢绳

- 沿海 / 酸碱腐蚀环境 → 合金钢丝热镀锌型号

- 卷筒与滑轮匹配

- 卷筒直径 ≥ 钢丝绳直径的 18~22 倍

- 滑轮直径 ≥ 钢丝绳直径的 16~20 倍

- 避免小直径卷筒过度弯曲,防止股结构松散

- 维护注意事项

- 定期加注钢丝绳专用润滑脂,减少钢丝磨损与锈蚀

- 检查时重点关注股间是否有断丝、变形,出现 3 丝以上断丝需及时报废

需要我帮你整理8×26WS+IWRC 与同规格 8×25Fi+IWRC 的性能对比表吗?8×26WS+IWRC钢丝绳的破断拉力是多少?8×26WS+IWRC钢丝绳的重量如何计算?8×26WS+IWRC钢丝绳的使用寿命有多长?

related products

Product Inquiry

Please leave your message, we will contact you quickly after receiving it, thank you for your support!

common problem

Q

What kind of lubricant can prevent wire rope damage?

A

First, the smooth oil has good fluidity and soaking ability, allowing it to quickly enter the inside of the rope and the rope core when the wire rope is smooth pretreated, and can play a role in preventing bacteria from multiplying inside the rope core fibers.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Q

What are the classifications of wire ropes?

A

1, electric hoist wire rope: 6 * 37 + FC- 11/13/15/17.5

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

Copyright © 2012-202X Jiangsu Dingtian Technology New Materials Co., Ltd. All rights reserved

简体中文

简体中文 English

English