Product

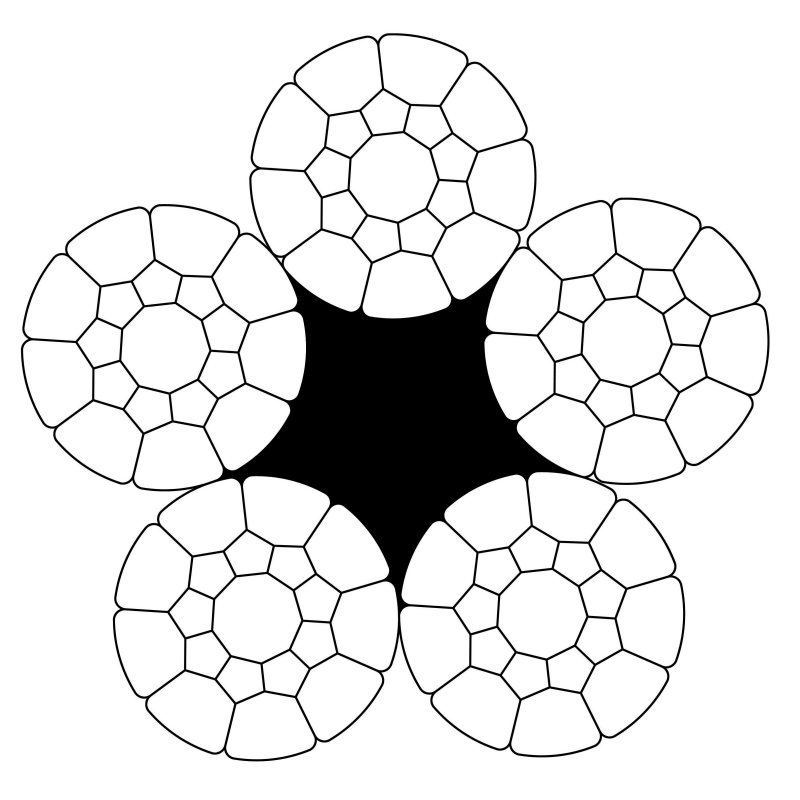

8×K26WS-IWRC

A company specializing in the production, research and development, and sales of steel wire ropes. It develops and produces supporting services for elevator rope manufacturers, focusing on 6 * 19 steel wire ropes. At the

- Product details

-

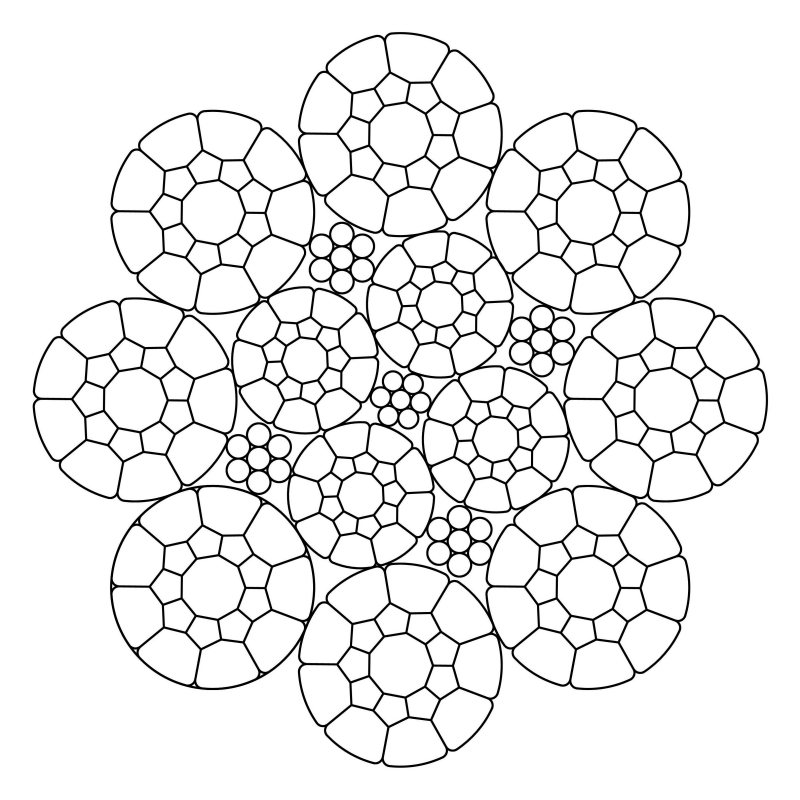

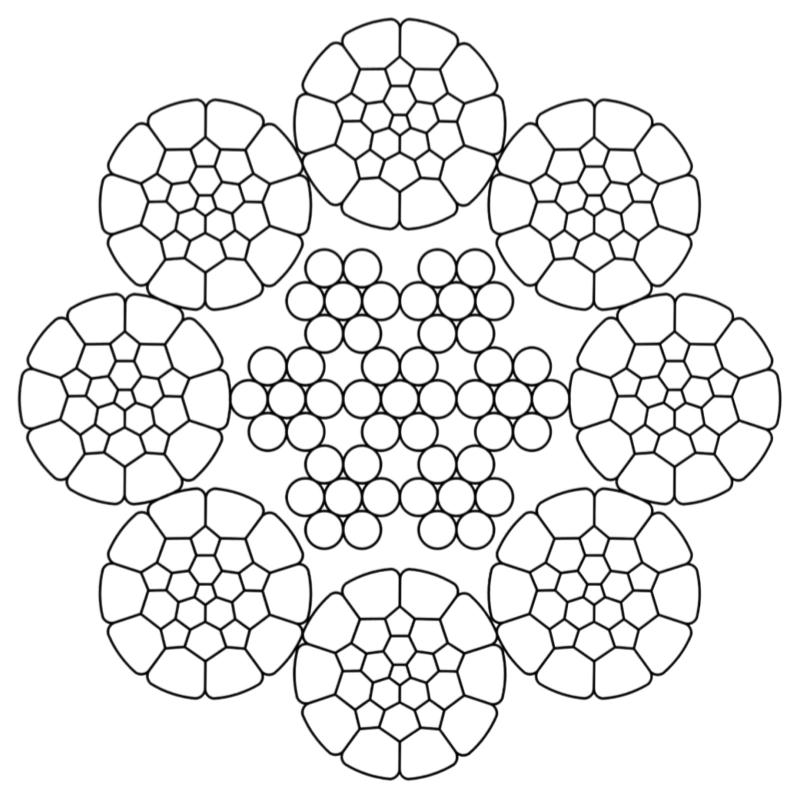

8×K26WS-PWRC (K) 是一款8 股 K 型压实瓦林吞 - 西鲁式股 + 平行钢丝绳芯的高强度低旋转压实钢丝绳,符合 GB/T 8918-2016 与 EN 12385-4 标准,适配大型履带吊主钩、港口集装箱起重机、海上浮吊、钢厂冶金起重机等对超高强度、抗挤压、多层缠绕、低旋转有严格要求的重型作业工况。

型号含义拆解

型号部分 含义说明 8 外层 8 个工作股,对称排列配合交叉捻向,抵消扭转扭矩,实现低旋转,避免重载吊装时吊钩打转、货物摆动 ×K26WS K 型压实瓦林吞 - 西鲁式股(WS=Warrington-Seale 瓦西结构),每股 26 根钢丝(粗细搭配 + 填充丝),冷压实后股径缩小、钢丝面接触,金属利用率与抗疲劳、抗磨损性能大幅提升 -PWRC(K) 平行钢丝绳芯(Parallel Wire Rope Core),K 代表整体压实结构,芯丝平行排列无捻制,提供更高支撑刚度、抗挤压能力与承载效率,适配多层缠绕,强度与稳定性优于普通 IWRC 型号 一、基础结构参数

参数项 详细说明 结构组成 8 个 K 型压实瓦西式外层股 + 平行钢丝绳芯(PWRC (K)),外层股与绳芯交叉捻向,绳体圆整致密,低旋转,抗挤压性强 钢丝材质 优质高碳钢(#82B、#925),冷拔强化 + 股 / 绳整体压实处理;表面可选热镀锌 / 电镀锌 / 光面,适配不同腐蚀工况 表面处理 1. 热镀锌:镀层厚 30~60μm,适用于海上、高盐雾等强腐蚀重载场景2. 电镀锌:镀层厚 8~15μm,适用于干燥室内重型起重工况3. 光面:无镀层,需定期加注专用润滑脂,适配高精度重型吊装场景 直径范围 常见 16~64mm,主流应用 24~56mm 重型提升 / 牵引场景 公称抗拉强度 1770MPa、1960MPa、2160MPa(重型重载优先选 1960MPa,平衡强度与耐疲劳性) 重量系数 0.520~0.550(比同规格 8×K26WS-FC 重 25%~30%,强度与抗挤压性能显著提升) 最小破断拉力系数 0.400~0.420(K 型压实 + PWRC (K) 协同,金属利用率比普通 8×26WS+FC 提升 18%~22%) 二、典型力学性能表(1960MPa 热镀锌 + PWRC (K) 芯)

公称直径(mm) 参考重量(kg/100m) 最小破断拉力(kN) 适用场景 24 220 1050 中型履带吊主钩绳、港口门式起重机主起升绳 32 380 1900 大型建筑塔吊主绳、矿用提升设备主绳 40 580 2950 港口集装箱起重机主绳、海上浮吊辅助绳 48 820 4250 钢厂冶金起重机主绳、重型预制件吊装绳 注:热镀锌对破断拉力影响<2%;平行钢丝芯无捻制,芯部损伤风险低于普通钢绳芯,维护周期延长 15%~20%。三、核心特性

- 超高强度,适配重型重载K 型压实股与平行钢丝芯协同,整体破断拉力比同规格 8×K26WS-IWRC 提升 8%~12%,适配 100~300 吨级起重设备的主起升机构,满足重型货物的长期稳定吊装需求。

- 极致抗挤压,适配多层缠绕平行钢丝芯的高支撑刚度与 K 型压实股的致密结构,让绳体在多层缠绕时股间变形量减少 30%~35%,降低断丝风险,适配大型卷筒的高频次起升下放作业。

- 低旋转高稳定,保障精准作业8 股对称排列 + 交叉捻向,有效抵消扭转扭矩,重载吊装无明显旋转,避免货物摆动、吊钩打转,保障海上、冶金等高精度重载作业的安全性与精准度。

- 耐磨耐疲劳,寿命长瓦西式股结构让外层钢丝接触均匀,压实工艺减少微动摩擦,耐疲劳性能是普通 8×26WS+FC 的 2.0~2.4 倍,降低设备运维成本。

四、选型与使用要点

- 安全系数选择

- 大型履带吊主钩 / 港口集装箱起重机:9~11 倍

- 海上浮吊 / 钢厂冶金起重机:11~13 倍

- 严禁用于强酸碱腐蚀无防护、超重型长期悬挂、高温(>150℃)等极端工况

- 环境适配原则

- 干燥室内重型起重 → 电镀锌型号

- 户外 / 海上 / 矿山强腐蚀环境 → 热镀锌型号,定期加注防腐润滑脂

- 强腐蚀环境 → 搭配聚氨酯(PU)护套,隔绝腐蚀介质

- 卷筒与滑轮匹配

- 卷筒直径 ≥ 钢丝绳直径的 26~31 倍

- 滑轮直径 ≥ 钢丝绳直径的 24~29 倍

- 滑轮槽底为圆弧深槽精密加工,匹配绳径,避免股丝受力不均断丝

- 维护注意事项

- 定期加注钢绳芯专用防腐润滑脂,高压注脂确保渗透至股间和绳芯缝隙

- 检查重点为股端断丝、绳径磨损、镀层脱落、芯部损伤,单股 2 丝断丝或芯部损伤立即报废

- 运输存放用专用支架盘卷,避免挤压变形、划伤镀层;长期存放于干燥通风处,定期防锈检查

需要我帮你整理8×K26WS-PWRC (K) 与 8×K29Fi-IWRC 的性能对比表吗?8×K26WS-IWRC8×K26WS-IWRC 钢丝绳核心参数与性能

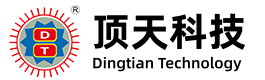

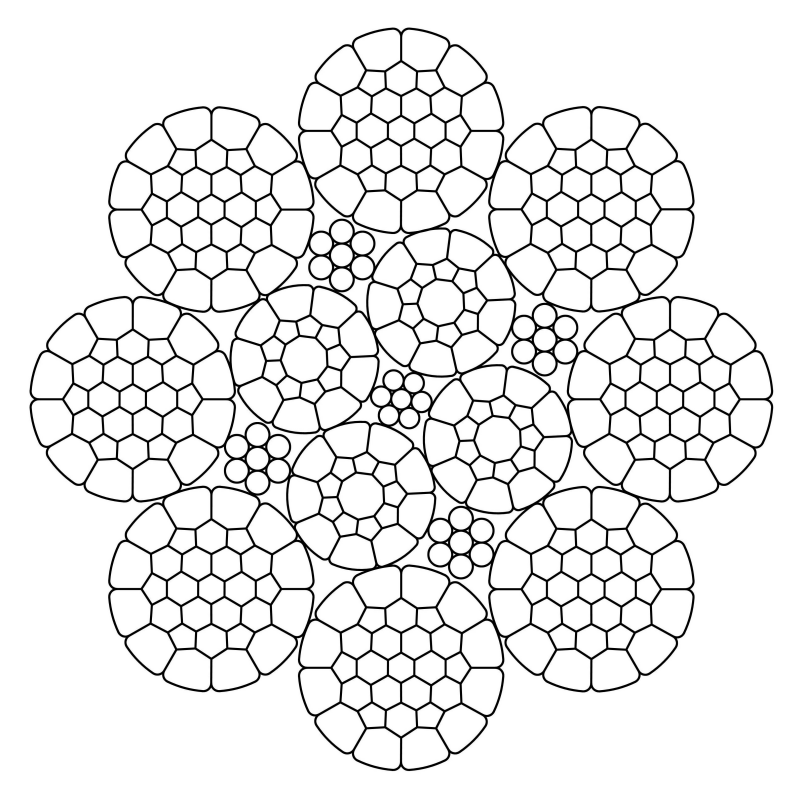

8×K26WS-IWRC 是一款 8 股 K 型压实瓦林吞 - 西鲁式股 + 独立钢丝绳芯 的中重型低旋转压实钢丝绳,符合 GB/T 8918-2016《重要用途钢丝绳》标准,适配中型履带吊主钩、港口件杂货起重机、建筑大型塔吊起升机构、矿用提升设备等对重载、抗挤压、多层缠绕有需求的作业工况。型号含义拆解

型号部分 含义说明 8 外层为 8 个工作股,对称排列设计配合交叉捻向结构,可有效抵消承载时的扭转扭矩,实现低旋转特性,避免中重型吊装时吊钩打转、货物摆动 ×K26WS K 型压实瓦林吞 - 西鲁式股(WS=Warrington-Seale 复合结构),每股由 26 根粗细交替钢丝排布而成,经冷压实工艺处理后股径缩小、钢丝贴合紧密,金属截面积利用率大幅提升,抗疲劳、抗磨损性能远超普通捻制股 -IWRC 独立钢丝绳芯(Independent Wire Rope Core),常规为 7×19 结构,由独立钢绳捻制而成,提供稳定的径向支撑力与抗挤压能力,适配多层缠绕工况,避免绳体变形、断丝 一、基础结构参数

参数项 详细说明 结构组成 8 个 K 型压实瓦西式外层股 + 独立钢丝绳芯(IWRC);外层股与绳芯采用交叉捻向(外层右捻、芯左捻),绳体圆整度高,旋转扭矩低,抗挤压性能优于纤维芯同类型号 钢丝材质 优质高碳钢(#82B、#925),经冷拔强化 + 股压实处理;外层股与绳芯钢丝表面可选热镀锌 / 电镀锌 / 光面,按需匹配不同腐蚀工况 表面处理 1. 热镀锌:镀层厚 30~60μm,适用于沿海高盐雾、矿山潮湿等中强腐蚀中重载场景2. 电镀锌:镀层厚 8~15μm,适用于干燥室内中重型起重工况3. 光面:无镀层,需定期加注专用润滑脂,适用于高精度中重型吊装场景 直径范围 常见 14~56mm,主流应用 20~48mm 中重型提升 / 牵引场景 公称抗拉强度 高碳钢型:1770MPa、1960MPa、2160MPa(中型重载设备优先选用 1960MPa 等级,兼顾强度与耐疲劳性) 重量系数 0.500~0.530(比同规格 8×K26WS-FC 重 20%~24%,比 8×K26WS-PWRC (K) 轻 4%~6%) 最小破断拉力系数 0.380~0.400(K 型压实工艺 + IWRC 绳芯协同作用,金属利用率比普通 8×26WS+FC 系列提升 16%~21%) 二、典型力学性能表(1960MPa 热镀锌 + IWRC 芯)

公称直径(mm) 参考重量(kg/100m) 最小破断拉力(kN) 适用场景 20 160 750 中型塔式起重机起升绳、港口门式起重机牵引绳 28 310 1400 中型履带吊主钩绳、港口件杂货起重机主起升绳 36 520 2350 大型建筑塔吊主绳、矿用提升设备主绳 44 780 3550 中型港口卸船机主绳、重型预制件吊装绳 注:热镀锌处理对破断拉力的影响小于 2%;IWRC 绳芯的刚性支撑特性,可减少多层缠绕时的股间挤压变形。三、核心特性

- 中高承载抗挤压,适配多层缠绕工况K 型压实股提升外层耐磨与抗挤压能力,IWRC 独立钢绳芯提供稳定径向支撑,能承受中型履带吊、港口起重机的多层缠绕挤压应力,减少股间变形、断丝风险,适配高频次起升下放作业。

- 低旋转高稳定性,保障精准吊装8 股对称排列 + 交叉捻向设计,有效抵消绳体承载时的扭转扭矩,中重型吊装时吊钩无明显旋转,货物摆动幅度小,满足建筑塔吊、矿用提升设备的高精度作业需求。

- 耐磨耐疲劳,使用寿命长瓦林吞 - 西鲁式股的外层粗钢丝与滑轮、卷筒接触面积均匀,磨损速率低;压实工艺让股内 26 根钢丝紧密贴合,减少微动摩擦损耗,耐疲劳性能是普通 8×26WS+FC 钢丝绳的 1.8~2.2 倍,降低设备运维成本。

- 防腐性能可控,适配多环境作业热镀锌镀层附着力强,可抵御沿海盐雾、矿山潮湿等腐蚀环境;搭配钢绳芯专用防腐润滑脂,能有效隔绝潮气,维护周期比纤维芯型号延长 60% 以上。

四、选型与使用要点

- 安全系数选择

- 中型履带吊主钩 / 港口件杂货起重机:8~10 倍

- 大型建筑塔吊 / 矿用提升设备:10~12 倍

- 严禁用于强酸碱腐蚀无防护、超重型设备长期悬挂、高温(>150℃)等极端工况

- 环境适配原则

- 干燥室内中重型起重 → 电镀锌全绳型号

- 户外 / 矿山 / 沿海中强腐蚀环境 → 热镀锌型号,定期加注防腐润滑脂

- 强腐蚀环境 → 搭配聚氨酯(PU)护套,隔绝腐蚀介质

- 卷筒与滑轮匹配

- 卷筒直径 ≥ 钢丝绳直径的 24~29 倍

- 滑轮直径 ≥ 钢丝绳直径的 22~26 倍

- 滑轮槽底需为圆弧深槽精密加工,与绳径精准匹配,避免股丝受力不均引发断丝

- 维护注意事项

- 定期加注 钢绳芯专用防腐润滑脂,采用高压注脂设备,确保润滑脂渗透至股间和绳芯缝隙,不可使用纤维芯专用润滑脂

- 检查重点为 股端断丝、绳径磨损、镀层脱落、股间松动,出现单股 2 丝断丝时需立即报废

- 运输与存放时需盘卷整齐,使用专用支架避免挤压变形、尖锐物划伤镀层;长期存放置于干燥通风环境,定期检查防锈情况

related products

Product Inquiry

Please leave your message, we will contact you quickly after receiving it, thank you for your support!

common problem

Q

What kind of lubricant can prevent wire rope damage?

A

First, the smooth oil has good fluidity and soaking ability, allowing it to quickly enter the inside of the rope and the rope core when the wire rope is smooth pretreated, and can play a role in preventing bacteria from multiplying inside the rope core fibers.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Q

What are the classifications of wire ropes?

A

1, electric hoist wire rope: 6 * 37 + FC- 11/13/15/17.5

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

Copyright © 2012-202X Jiangsu Dingtian Technology New Materials Co., Ltd. All rights reserved

简体中文

简体中文 English

English