Product

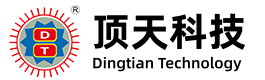

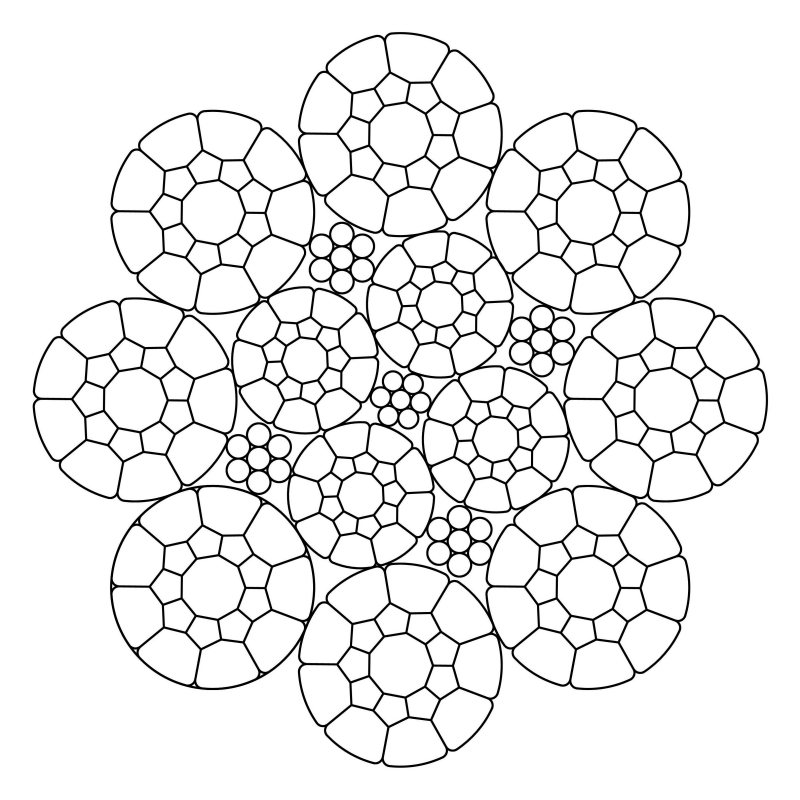

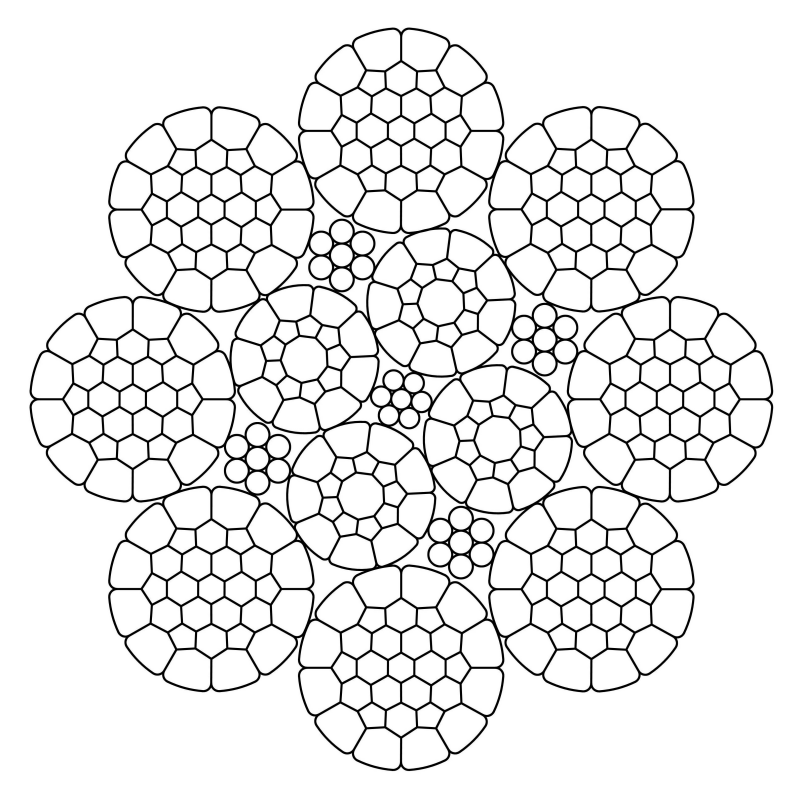

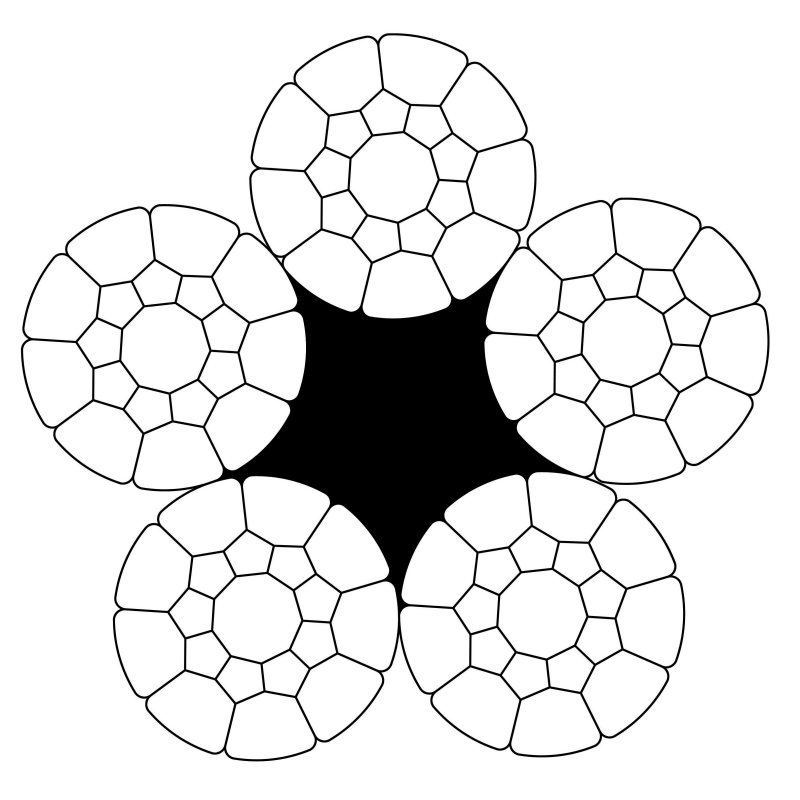

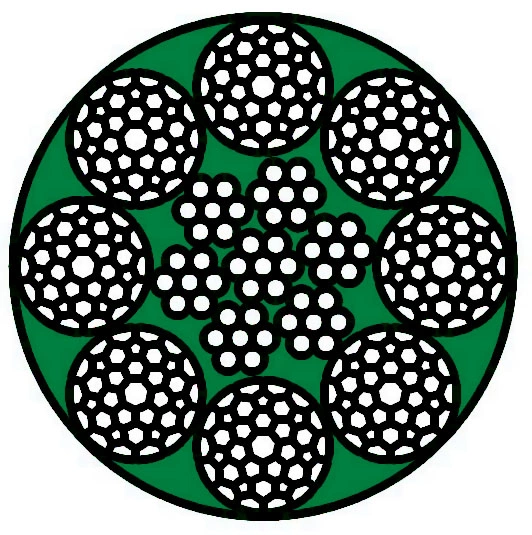

EP8×K36WS-IWRC

A company specializing in the production, research and development, and sales of steel wire ropes. It develops and produces supporting services for elevator rope manufacturers, focusing on 6 * 19 steel wire ropes. At the

- Product details

-

Plastic-Coated Compacted Strand Steel Wire Rope Technical Parameter Table

Product Advantages

- High wear resistance, extrusion resistance and strength

- The plastic coating protects the contacting pulleys and drums

- Filled plastic reduces friction between wires and extends service life

- Reduces rope replacement frequency and protects the working environment

- Excellent shock absorption performance

- Can be customized with other structures according to user requirements

Applications

- Main hoisting and pressure-increasing steel wire ropes for large electric shovels

- Main hoisting and luffing ropes for large draglines

Nominal Diameter of Steel Wire Rope (mm) Approx. Weight of Steel Wire Rope (kg/100m) Minimum Breaking Load of Steel Wire Rope (kN) Fiber Core Rope Steel Core Rope 1670MPa 1770MPa 1870MPa 1960MPa Fiber Core Steel Core Fiber Core Steel Core Fiber Core Steel Core Fiber Core Steel Core 16 10 131 160 170 179 189 196 206 210 220 18 12 164 192 225 224 234 250 264 259 281 20 14 206 260 271 283 351 297 371 320 389 22 16 243 295 317 343 336 419 442 373 463 24 18 274 338 432 457 358 494 581 507 630 26 20 318 365 466 561 526 643 655 680 723 30 24 365 507 594 701 679 753 733 795 823 32 26 413 568 652 637 705 839 866 864 947 34 28 468 652 714 787 877 941 980 938 1041 36 30 525 715 882 909 935 1161 981 1035 1260 38 32 608 792 975 890 1030 1280 1195 1245 1458 40 34 857 1047 1165 1146 1356 1365 1622 1369 1750 42 36 933 1240 1378 1422 1814 1422 1917 1617 2009 44 38 1013 1338 1490 1579 1962 1693 2073 1866 2173 46 40 1151 1443 1697 1732 2276 1799 2404 2028 2520 48 42 1336 1652 1728 2413 1965 2413 2576 2176 2703 50 44 1620 1782 1984 2465 2103 2600 2270 2328 2993 52 46 1750 1980 2160 2530 2390 2790 2590 2950 — 54 48 1980 2160 2550 2980 2540 3160 2690 3340 — 56 50 2120 2300 2750 3170 3360 3560 3290 3750 — 58 52 2300 2650 3459 3600 3760 3920 3960 3970 — 60 54 2218 2711 3018 3749 3099 3974 3379 4198 —

related products

Product Inquiry

Please leave your message, we will contact you quickly after receiving it, thank you for your support!

common problem

Q

What kind of lubricant can prevent wire rope damage?

A

First, the smooth oil has good fluidity and soaking ability, allowing it to quickly enter the inside of the rope and the rope core when the wire rope is smooth pretreated, and can play a role in preventing bacteria from multiplying inside the rope core fibers.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Second, the lubricating oil adhered to the wire rope will not be easily wiped off, and the smoothing effect will not be affected within the specified temperature range. In addition, the lubricating oil with adhesive function can also prevent skid, which provides assistance for the friction of the elevator wire rope.

Third, it has a high oil film strength, which can resist the extremely high pressure between the steel wires in contact with each other under extremely heavy load, and can also resist decomposition and transformation.

Fourth, smooth oil has high cohesion, which can avoid the dripping of smooth oil, centrifugal loss when there is no exercise, and avoid grease waste and pollution to other equipment.

Fifth, it does not contain ingredients that can cause corrosion and rust in the steel wire rope, and the effect of anti-corrosion and anti-rust is better.

Sixth, its self-correcting ability is strong. When the wire rope is used, it constantly twists and turns, which will cause the surface oil film to continuously knead and expand. This requires a soft and high-temperature oil film to maintain the rope body from cracking.

Q

What are the classifications of wire ropes?

A

1, electric hoist wire rope: 6 * 37 + FC- 11/13/15/17.5

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

2, tower crane wire rope and multi-strand non-rotating wire rope: 6 * 19 + FC- 12/12.5, 6 * 37-13/14, 6 * 29FI + FC- 12/12.5, 4v39s + 5FC- 12/13/14, 35W * 7-12/13/14

3, car crane does not rotate wire rope: 4V39S + 5FC- 10/12/13/14/16/17, 35W * 7-10/12/13/14/15/16/17/18/20/22

4, pile driver flat wire rope: K6K36WS + IWR-/17.5/24/26/28/30/32/34/36/40/42/46

5, rotary excavator flat wire rope: 35W * K7- 24/26/28/30/32/36/40

6, dock crane wire rope: 6 * 36WS + IWR- 17.5/19 5/21.5/24/26

7, mine wire rope 6 * 19 + FC- 12.5/14/15.5/17/18.5/21 5/24.5/26/28, 6 * 19S + FC- 12.5/14/15.5/17/18.5/21 5/24.5

8, elevator wire rope: 8 * 19S + FC- 10/11/12/13/16

9. Hot-dip galvanized hanging basket wire rope: 4 * 31WS + PPC- 8.3/8

10. Hot-dip galvanized wire rope: 6 * 19/6 * 37/6 * 36WS/8 * 61/8 * 36WS/

11, galvanized wire rope: 6 * 7 + FC-/2/3/4

6 * 19 + FC-5/6/7 7/9.3/11, 6 * 12 + 7FC-5/6/7. 7/9.3/11, 7 * 19-5/6/8/10, 19 * 7-4/5/6/8/10, 6 * 37 + FC-8.7/9 3/11/13/15/17.5/19.5

12. Large diameter wire rope: above 60MM

13. Wire rope rigging (insertion, pressing, pouring, connectors, etc.):

14, coated wire rope: 2-3/3 - 4/4-5/5-6/6 - 8/8-12/12-15

15, binding wire rope: 6 * 12/6 * 15-13/14/15

The front represents the structure, and the back represents the diameter. For example: 6 * 37 + FC-11, the representative structure is 6 * 37 + FC, diameter: 11MM

Copyright © 2012-202X Jiangsu Dingtian Technology New Materials Co., Ltd. All rights reserved

简体中文

简体中文 English

English